Hi All, do you know which information model in TRACI the carbon impact of construction waste management and diversion factors in? I believe the hauling is captured in A5 but what about the recycling or disposal of the materials? Does this require a different tool perhaps using the EPA’s WARM tool?

Thanks!

Hi Kai,

Are you asking about reporting A5 emissions for LEED v5? If so, a new LEED v5 tool for North America will be launching soon. This tool will let you report A5 emissions under the ‘construction site operations’ tab, similar to the existing carbon tools for North America.

How A5 emissions are captured really depends on your calculation method. We offer a few options:

- You can accurately report project-level construction waste numbers if you have those specific quantities. This would include the waste generated, the transport emissions would then be generated based on the weight of the amount of waste, often transported in dump trucks.

- Another option, though not currently in our LEED tool, is to use a waste percentage assigned to materials. This is a common method and is present in about 90% of other tools.

- We also offer A5 construction scenarios, some of which are proprietary and others based on regulatory or certification guidance.

How this looks in e.g. our BREEAM tool (it will likely look similar for our LEED v5 tool):

Inputs:

Outputs:

I’m not very familiar with the EPA WARM tool, but if it provides the necessary quantities, you should be able to include them in your assessment.

I hope this clarifies things! Let me know if you have any other questions.

Hi, I’m asking about LEED v4.1 though that’s interesting about v5 calculations. In the screenshot below, does A5d Construction Site Material Wastage account for the site construction waste management like if we had a 75% recycling rate?

Kai Starn

Senior Sustainability Consultant

203.857.0200 x3240

Steven Winter Associates

Hi Kai,

Thanks for the update.

Regarding your query, our v4.1 framework doesn’t mandate reporting on A5, so we haven’t included these emissions. Globally, the most prevalent methodology is to account for all waste-related emissions within the A5 category, covering wastage, transport, recycling and disposal.

In the example of my screenshots, A5d and A5d-leg2 address waste transportation. We calculate this based on the wastage percentage (e.g., 2% of ready-mix concrete waste that’s downcycled to aggregate), with the recycling process itself falling under A5e.

Presently, we assume 100% of construction site waste follows a single end-of-life process (e.g., all concrete is downcycled). While you can define separate end-of-life processes (C1-C4) for your included construction materials, this level of granularity isn’t yet common for A5.

Is this an area you’re looking to optimize for your clients, perhaps by tracking more specific end-of-life pathways for A5 waste? We’re very interested to hear your insights on this.

Thanks Steven! I work mainly with LEED projects, with over 30 certified to date, and projects often target higher rates of construction waste diversion (for our area) up to 90%+ recycling of construction waste. I guess I’m curious what the impacts of diverting from the landfill are compared to typical waste disposal <50% diversion. Even a rule of thumb to use for consulting would be useful as projects aim to decarbonize, e.g., every pound of steel/concrete/drywall/insulation diverted from the landfill and recycled avoids 100 kg/CO2e. I’m sure it gets complex because we’re using more energy to recycle it, but avoiding virgin material impacts.

Hi Kai,

Thanks for elaborating. You’re right, understanding the avoided impact of recycling is crucial. While recycling processes do require energy, the consensus is that the benefits of avoiding virgin material production and landfill emissions significantly outweigh those energy costs.

While we don’t have our own “rules of thumb,” I’ve pulled some indicative ranges from the EPA WARM tool that might be helpful for your consulting:

- Steel: Very high savings (e.g., 1.5-2.5 tCO2e avoided per tonne)

- Concrete: Moderate savings, mainly from avoiding virgin aggregate (e.g., 0.01-0.05 tCO2e avoided per tonne)

- Drywall: Good savings, partly due to avoided landfill methane (e.g., 0.05-0.15 tCO2e avoided per tonne)

- Insulation (depends on the type): High savings (e.g., 1.0-2.0 tCO2e avoided per tonne)

Keep in mind, these are general guidelines. For precise figures, it’s best to use the EPA WARM tool directly, as it accounts for various factors. You can access the Excel version here: https://www.epa.gov/system/files/documents/2023-12/warm_v16.xls.

You can also calculate these comparative impacts directly in One Click LCA, which requires a bit of work, though:

- Input Waste Quantity: Enter the total quantity of material that would become waste (e.g., 1000 kg).

- Compare End-of-Life Scenarios: Duplicate this entry. For one, set the end-of-life process to landfill. For the other, set it to recycling.

- Analyze C3/C4 Emissions: Compare the emissions for the C3 (waste processing) and C4 (disposal) stages. For example, 1000 kg of concrete:

- Downcycling to aggregates: ~0.35 kg CO2e

- Disposing to landfill: ~2.6 kg CO2e

- For a basic RMC the material distribution would be similar to the below:

The emissions we’d save from recycling concrete are primarily related to the aggregates, which account for about 5% of a ready-mix concrete’s emissions. This is why the EPA tool shows moderate savings for concrete recycling.

You might find that for some materials, the emissions from the recycling process itself are ‘technically’ higher than landfilling in a direct C3/C4 comparison due to energy use. However, the overarching benefit comes from avoiding virgin material production. For materials like steel and insulation, the positive impact of recycling is much more significant, as I’m sure you’re well aware.

Hope this helps!

Hi Steven, this is all very interesting and helpful thanks. I’m unsure if this next question should be a different thread, but here it goes:

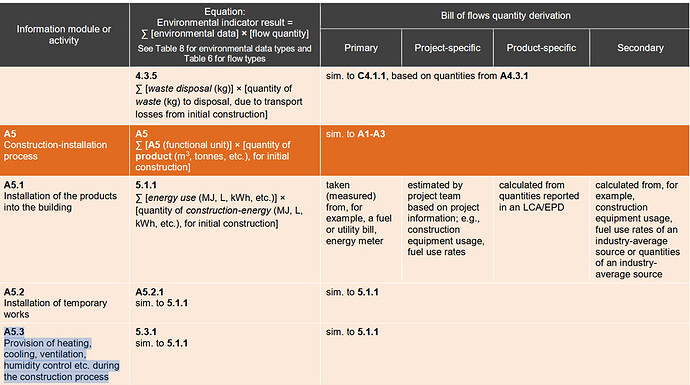

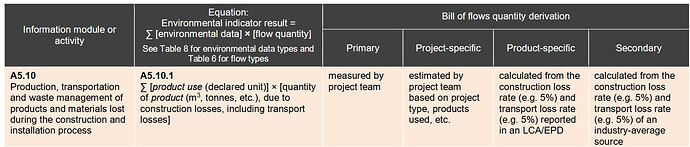

I’m reviewing the Bill of Flows for A5.3 and A5.10 modules and there appears to be confusion between what’s included in both across literature. Maybe you can help clarify!

First, ANSI 1550 references A5.3 with the intention of capturing construction waste during installation.

This A5.3 designation aligns with ASHRAE 240p, which is referencing the RICS methodology from the UK.

Here’s a clip from the RICS doc:

And from ASHRAE 240p (first public draft):

However, the Canadian National Research Council LCA publication for practitioners lists “provisions for heating, cooling, ventilation, humidity control etc.” in A5.3 and A5.10 as including “production, transportation and waste management of products…during the construction and installation process.”.

Lastly, LEED version 5 includes an option for tracking fuel usage onsite, and I’m unsure whether this falls into A5.3 or A5.10. The modules seem very different “asks” and I’m concerned the mismatch is going to confuse teams. Can you share your knowledge about what is in the bill of flows for A5.3 and A5.10?

Thanks in advance!

Hi Kai, I will get back to this tomorrow to take a look at this in-depth. I’m familiar with RICS and ASHRAE so I would personally follow their logic but tomorrow I’ll check the CNRC publication and give my final verdict. LEEDs fuel usage onsite should be attributed to 5.1-3 rather than 5.10 I think.

Hi again, I’ve reviewed the publication ‘National Whole-Building Life Cycle Assessment Practitioner’s Guide’ however I could not find the specific reference to A5.10. Would you be able to share a link to that document?

The sub-modules of A5 differ slightly across different standards and guides (I’ve crosschecked it against our entire collection of them), however A5.3 in virtually all is defined as ‘waste and waste management’ which roughly states the following in most guidance docs:

’This module is intended to capture the embodied carbon resulting from materials that are ultimately wasted on site. This includes the impacts associated with the production, transportation, storage, and end-of-life treatment and disposal of waste materials (including packaging waste) generated on-site’.

How far this expands and which other subcategories are reported, depend a bit on the schemes. E.g. in RICS there is a variety of new entries under A5 (like pre-construction demolition) which aren’t in any other scheme yet.

For onsite fuel usage and the such, as per RICS energy and water use for construction processes and heating/cooling/ventilation of site facilities are allocated to A5.2, or “Construction activities”. In LEED they just mentioned ‘LCA Module A5’ however my assumption is that in our upcoming LEED v5 tool, we will attribute it to A5.2 as well.

Why the CNRC document refers to A5.10 and why they handle A5.3 differently, I am still not certain. It is not aligned with the standard LCA models I am familiar with so I would like to see the original document and what assumptions they have made. I for now, would stick with the guidance from ASHRAE, ANSI 1550, RICS and EN15978 as these are all aligned to a degree.

Thanks for the deep dive. Interesting the modules don’t all align. These tables are from the Canadian National Research Council guide to LCA for practitioners using the referenced EN and ISO standards https://nrc-publications.canada.ca/eng/view/ft/?id=f7bd265d-cc3d-4848-a666-8eeb1fbde910.

Kai Starn

Principal Sustainability Consultant

203.857.0200 x3240

Steven Winter Associates

Thank you for sharing this, Kai. I made a mapping of the A5 categories between the NRC-CNRC and RICS 2nd edition standards.

While countries can develop their own methodologies for tracking emissions, new systems typically align with established frameworks rather than creating entirely new ones. Still important to familiarize ourselves with such systems, as any future national LCA regulation in Canada would likely adopt a similar reporting structure. (which in that case, we would of course integrate into the tool, so you wouldn’t have to worry about it really)

NRC-CNRC A5 vs RICS 2nd edition A5 (Subcategory Mapping)

| NRC-CNRC A5 Subcategory | RICS Equivalent | Notes |

|---|---|---|

| — | A5.1 Preconstruction demolition | No Canadian equivalent. RICS requires demolition/deconstruction impacts of existing structures at project start (linked to retrofit vs new-build choices). |

| A5.1 Installation of products (energy use) | A5.2 Construction activities | Both cover site energy (plant, equipment, site facilities). |

| A5.2 Installation of temporary works | A5.2 Construction activities | Included in RICS as temporary works (formwork, props, scaffolding, etc.). |

| A5.3 Provision of HVAC during construction | A5.2 Construction activities | RICS explicitly includes energy for heating/cooling/ventilation of site accommodation. |

| A5.4 HVAC for temporary works | A5.2 Construction activities | Same as above — falls under temporary works and site facilities. |

| A5.5 On-site transport (materials, waste, equipment) | A5.2 Construction activities | RICS lists transport and on-site storage of materials and equipment. |

| A5.6 Ground works & landscaping | A5.2 Construction activities | Included in RICS as site preparation & landscaping. |

| A5.7 On-site production/transformation (e.g. batching concrete) | A5.2 Construction activities | Included in RICS as “on-site production/assembly of products.” |

| A5.8 Storage of products (with heating, cooling, humidity) | A5.2 Construction activities | Included in RICS as on-site storage (with environmental controls). |

| A5.9 Water use & wastewater (machinery cooling, cleaning) | A5.2 Construction activities | Included in RICS as energy & water use for construction. |

| A5.10 Construction/packaging losses & waste | A5.3 Waste and waste management | RICS A5.3 covers product and packaging waste, including treatment and disposal. |

| A5.11 Ancillary materials (adhesives, fasteners, foams, etc.) | A5.2 Construction activities | Included in RICS under “works for installation and ancillary materials.” |

| A5.12 Temporary works (materials & transport, incl. off-site) | A5.2 Construction activities | Included in RICS temporary works scope. |

| A5.13 Waste management of ancillary & temporary works | A5.3 Waste and waste management | Fits into RICS waste category. |

| A5.14 Capital goods (machinery, trucks, cranes manufacturing) | Explicitly excluded in RICS; only their operational use (fuel/energy) is counted. | |

| — | A5.4 Worker transport (optional) | No Canadian equivalent. RICS allows optional reporting of worker commuting. |